Iron recycling plants and equipment DANIELI HENSCHEL

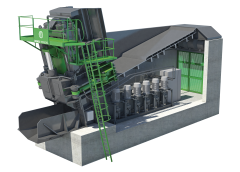

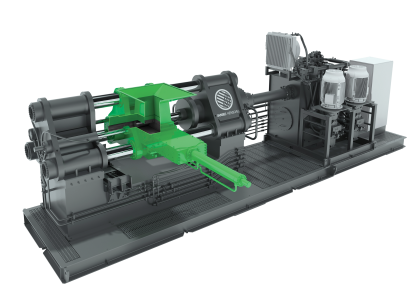

SCRAP SHEARS

Over the last 40 years or more, Danieli Henschel hydraulic scrap shears have acquired a worldwide reputation in the field of metal collection and recycling. Today, three major lines of hydraulic scrap shears (CIB, CIC & CIV) allow scrap metal processors to cope with every type of requirement. These scrap shears are designed to cut scrap metal using a guillotine system powered by hydraulic energy.

Because of the different reducer kinematics in each range, Danieli Henschel machines can process heavy, bulky scrap metal just as easily as lightweight scrap metal. They also increase the density of the scrap metal collected, while greatly reducing its size. This enables them to process dozens of tonnes per hour whatever the operating mode: automatic or manual.

Push here for getting more information.

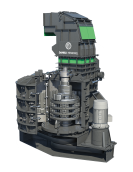

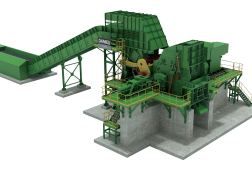

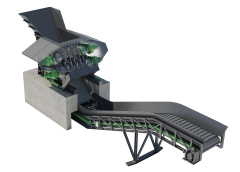

SHREDDERS

Through a continuous process of product development, Danieli Lynxs scrap shredder plants combine technical ingenuity with engineering excellence. We deliver scrap shredders starting from 600kW (800 Hp) right up to 7,500kW (10,000 Hp) that offer world leading performance and reliability at industry leading low operating costs.

A complete service is available to the scrap shredder operator from full turnkey design, manufacture and installation of new integrated facilities to the supply of replacement rotors and wear parts. At existing sites, our experienced engineers can offer new insight and practical solutions to modernise and enhance production output, metal recovery and overall efficiency.

Our robust and reliable plant is designed and built to meet the arduous conditions imposed when processing heavier grades of scrap metal.

Our innovative mill geometry and one-touch computer based control system gives high throughput with low power consumption. Comprehensive material disintegration ensures optimum separation and nonferrous product yield. State of the art dust extraction, suppression and control techniques mean that all our equipment meets current and foreseeable statutory environmental requirements.

Push here for getting more information.

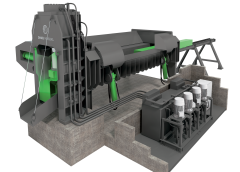

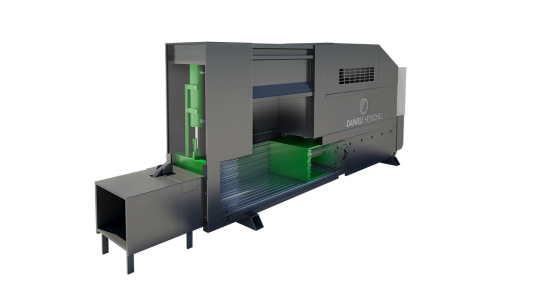

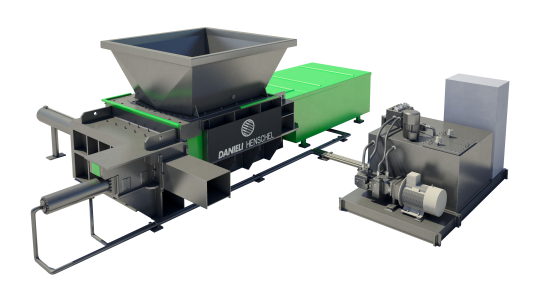

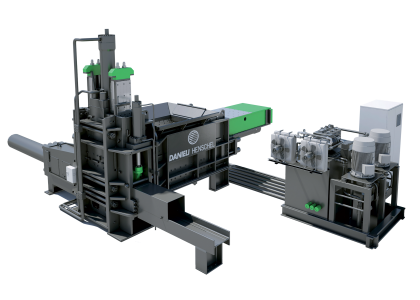

BALING PRESSES

Danieli Henschel baling presses are intended to reduce metal scrap for the best possible recycling thanks to maximum densification. The quality of the bales obtained optimises the recycling of recovered metal material. Transport costs are considerably reduced and storage and handling are facilitated.

In the steel foundries where they are melted, these high density bales guarantee the best possible performance of the furnace.

Danieli Henschel presses are designed to be operated under the most demanding conditions and suit the needs of recycling companies as well as the needs of industry. Their robust mechanical structure, their latest-generation hydraulic power packs and their automatic operation provide the operator with the superior reliability, production output and working life the business requires.

Push here for getting more information.